Date: ____________________________________

Supervisor: _______________________________

Company Name: _____________________________

Job Name: ______________________________

Guidelines for Discussion:

Heavy equipment is common while working on a construction site. Heavy equipment is integral to many processes, especially in the creation and maintenance of roads. Here are the different kinds of heavy equipment you may encounter at work:

- Excavation equipment: this includes backhoes, excavators, and front-end loaders

- Lifting equipment: the most common piece of lifting equipment is a crane

- Loading/hauling equipment: this includes loaders, bulldozers, scrapers, dump trucks, and wagons

- Compaction equipment: this includes different kinds of rollers

- Grading/finishing equipment: this includes different kinds of graders

- Paving/surfacing equipment: this includes aggregate spreaders, asphalt distributors, blowers, and pavement profilers

Heavy equipment is dangerous due to its size, weight, and complex operating procedures. However, though these hazards can be greatly reduced through proper awareness and training. Some common hazards of heavy machinery include:

- Poor repairs or outdated equipment

- Dirty or broken windows (these can obstruct the operator’s view)

- Struck by/caught in/between accidents can occur, wherein surrounding workers are hit by the equipment or pinned between the equipment and another object/environmental fixture

- Traveling empty at high speeds

- Riders falling off equipment

- Equipment overturning

- Runaway machines (either from failure to block the wheels upon parking or the operator’s inability to control)

- Electrical shock due to contact with overhead or underground power lines

- Collision with people, buildings, vehicles, or environmental fixtures

Remember, only authorized persons can operate heavy equipment. A worker becomes authorized by undergoing training or acquiring a license. If you are an operator, you are responsible for knowing and understanding the limitations of the machinery. Always follow safe operating procedures, use available safety features, and read the manufacturer’s warnings. If you are an operator and you are sick, fatigued, or otherwise impaired from performing your job, then you must notify your supervisor. Never try to power through a physical or mental condition that affects your ability to work – this brings unnecessary risk to you and everyone around you.

Before the start of each shift, the on-site operator should use the following checklist:

- Walk fully around the equipment and check for hazards (this includes deflated tires, damaged framework, or environmental fixtures that could potentially affect the machine).

- Check the equipment’s lights, suspension and steering system, fluid levels, and any external hoses and filters. Look for unguarded moving parts or other unsafe conditions.

- Enter the cab and remove any trash. Make sure all windows are clean, adjust mirrors, check the fire extinguisher, turn on all exterior lights, and make sure the seatbelt is ready to use.

- Start the engine, check gauges and warning lights, and listen to the engine for any unfamiliar sounds.

- Before moving, notify any people in the surrounding area.

- Test the equipment’s movements and make sure back-up alarms can be heard.

Even if you aren’t an operator, there are special safety protocols you must follow when working near heavy equipment:

- Wear high visibility clothing.

- Do not assume operators can see you – be careful where you stand.

- Appoint a signal person to assist the operator.

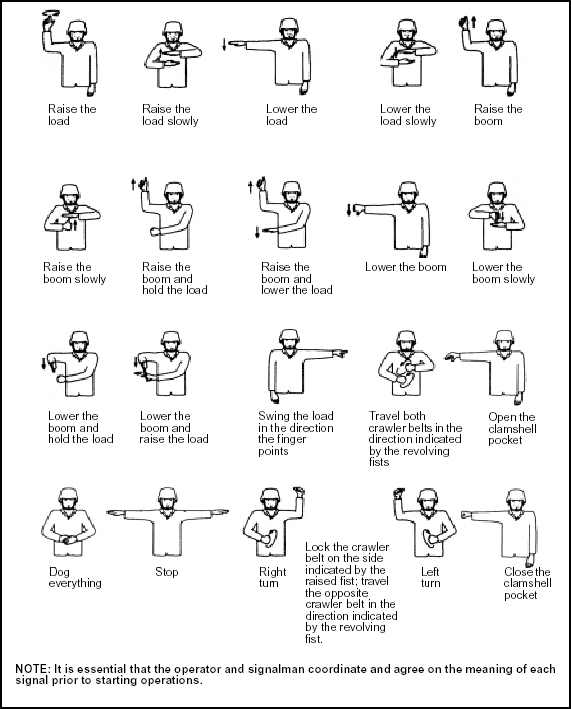

- Learn and use standardized hand signals.

- Use walkie-talkies or other communication equipment between the ground and the operator.

- Heed back-up alarms, and immediately notify the operator if the back-up alarms aren’t working.

Additional Discussion Notes:

At the end of this toolbox talk, go over the standardized hand signals with your employees. You may also appoint a signal person for communicating with the operator while on-site.

Safety Recommendations: _____________________

Job Specific Topics: ___________________________

Attendees:

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

____________________________________

Disclaimer

The information contained within this document (both the online and downloadable version) is provided for informational purposes only. Nobody shall take this as a comprehensive or exhaustive resource on this topic. This material is believed to be accurate, however, the information has been compiled from multiple sources, and so Industrial Compliance & Safety assumes no responsibility for the accuracy of this information. We encourage you to consult experts about this specific Toolbox Talk to ensure you are compliant with any and all safety regulations and processes. In no event does the content of this document supersede any applicable local, state, or federal statutes or regulations.